It is no secret that the augmented and virtual reality market is expanding by the day. The technologies produced by developers have finally matured enough for several industries to use. Manufacturers are also finding new ways to adopt these technologies in different areas of the industry like product development, training, and worker safety. Flex is a $25-billion service electronics design & manufacturing services provider. They have predicted that VR will expand even further than that in the manufacturing industry. In fact, they view it as so important that they have adopted manufacturing as one of their six key pillars of its Industry 4.0 strategy.

EMS companies like Flex are in a unique position and this specific company has over 100 facilities worldwide that are used for outsourcing to manufacturers. Manufactures on their own do not have huge profit margins. This is where EMS providers step in to close the gap. They add value through design, process improvement, and after-market services. Many people believe that AR/VR technologies will soon catch on. If this happens combined sales might hit the $150-billion mark in 2020 with AR alone comprising $120 billion of that figure.

One of the most important aspects that need to be taken into account is connectivity. Buzzwords are often thrown around like IoT & M2M which touches on the machined aspect of AR/VR technologies. Most enterprises are making use of tools like remote assistance for their internal uses benefit, also to integrate it into the business itself. How manufacturing data has been captured in the past has been slow, costly, and Flex sees the need for more efficient connectivity. AR could even go as far as to show the user the different techniques required to perform a task.

It is often difficult for the designer to account for every single step of the design process. This is where AR comes in handy. With AR technologies designers can display or project annotations, insert bubbles with more information, and even have manuals pop up that help with the application. VR, on the other hand, can be used to give the customer a taste of what the result will look like. If customers ask how a product is laid out, it is not always possible for them to poke their heads into the machine while it is working. With VR it is entirely doable.

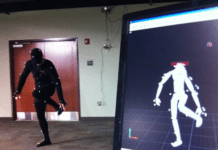

Flex predicts that AR/VR technologies will assist employees with training which will improve product development. Rather than training workers on the floor in unrealistic situations, VR can be used to simulate something closer to reality. Flex also mentions that this means that headsets will have to improve. At the moment it is big & bulky. This would be uncomfortable to wear the whole day. They envision the employee as a consumer as well; the product that they buy has to be an upgrade to what they have on the market at the moment.